If you’re a student studying machinery in the field of pharmaceuticals (D.Pharma), it means you are focusing on the study of pharmaceutical equipment and machinery used in the manufacturing and production processes. Here are some key areas you might cover in your studies:

- Manufacturing Equipment: You will learn about the various types of machinery and equipment used in pharmaceutical manufacturing, such as mixing and blending machines, milling equipment, granulators, drying equipment, tablet presses, encapsulation machines, and packaging equipment. You will study their principles of operation, design, and their roles in different stages of pharmaceutical production.

- Quality Control Instruments: Quality control is crucial in pharmaceutical manufacturing to ensure the safety, efficacy, and consistency of the final products. You will study analytical instruments and equipment used for quality control testing, such as high-performance liquid chromatography (HPLC), gas chromatography (GC), spectrophotometers, dissolution testers, and particle size analysers.

- Automation and Process Control: With advancing technology, automation plays a significant role in pharmaceutical manufacturing. You will learn about programmable logic controllers (PLCs), process control systems, and supervisory control and data acquisition (SCADA) systems used to monitor and control manufacturing processes. Understanding these systems will help optimize productivity, efficiency, and adherence to quality standards.

- GMP and Regulatory Compliance: Good Manufacturing Practices (GMP) are essential in the pharmaceutical industry to ensure the quality and safety of drugs. You will study the regulations and guidelines set by regulatory bodies, such as the FDA, EMA, and WHO, regarding equipment qualification, validation, calibration, and maintenance to meet GMP requirements.

- Safety and Maintenance: Safety is of utmost importance in pharmaceutical manufacturing. You will learn about safety protocols, hazard identification, risk assessment, and preventive measures associated with pharmaceutical machinery. Additionally, you will study equipment maintenance procedures to ensure optimal performance, reliability, and compliance with regulatory standards.

- Process Optimization and Scale-up: Pharmaceutical processes need to be optimized for efficiency and scalability. You will learn about process optimization techniques, such as Design of Experiments (DoE), statistical process control, and scale-up considerations when transitioning from laboratory-scale to commercial-scale production.

- Emerging Technologies: You may also study the latest trends and advancements in pharmaceutical machinery, such as continuous manufacturing, 3D printing of dosage forms, robotics, and data analytics. Understanding these emerging technologies will provide insights into the future of pharmaceutical manufacturing.

It’s important to note that the specific curriculum and depth of study may vary depending on your educational institution and program. Your coursework may include theoretical lectures, laboratory practicals, case studies, and hands-on training with pharmaceutical equipment. Now, let’s discuss in detail these points to further help you understand them.

➢ Manufacturing Equipment

Manufacturing equipment plays a vital role in pharmaceutical production, enabling the efficient and precise manufacturing of pharmaceutical products. Here are some common types of manufacturing equipment used in the pharmaceutical industry:

- Mixing and Blending Equipment: These machines are used to mix and blend various ingredients, including active pharmaceutical ingredients (APIs), excipients, and other additives, to ensure uniform distribution and homogeneity of the final product. Examples include high-shear mixers, ribbon blenders, fluidized bed mixers, and tumble blenders.

- Milling Equipment: Milling machines are used to reduce the particle size of raw materials, such as APIs and excipients. This helps in achieving uniformity, improving dissolution rates, and enhancing bio availability. Common types of milling equipment include hammer mills, ball mills, jet mills, and colloid mills.

- Granulation Equipment: Granulation involves the formation of granules by agglomerating powder particles. Granules facilitate proper flow, compression, and uniform drug distribution in solid dosage forms like tablets. Granulation equipment includes fluid bed granulators, high-shear granulators, and oscillating granulators.

- Drying Equipment: Drying is essential to remove moisture from wet granules or solutions, ensuring the stability and quality of the final product. Common drying equipment includes tray dryers, fluid bed dryers, vacuum dryers, and freeze dryers (lyophilizers).

- Tablet Presses: Tablet presses are used to compress granulated powders into tablets of specific sizes, shapes, and hardness. These machines apply controlled force to form tablets and often include features for tablet coating or imprinting. Tablet press machines can be single-station or multi-station rotary presses.

- Encapsulation Machines: Encapsulation involves filling capsules with powdered or liquid formulations. Encapsulation machines automate the encapsulation process, offering high-speed and accurate filling of capsules. Examples include capsule filling machines like manual, semi-automatic, and fully automatic capsule fillers.

- Packaging Equipment: Packaging equipment is used to package and label pharmaceutical products. This includes primary packaging (such as blister packaging, bottles, and vials) and secondary packaging (such as cartoning, labelling, and serialization). Packaging equipment may include blister packaging machines, labelling machines, cartons, and shrink-wrapping machines.

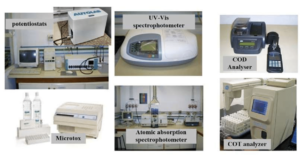

- Analytical Instruments: While not strictly manufacturing equipment, analytical instruments play a crucial role in quality control. They are used to analyse the chemical composition, purity, and potency of pharmaceutical products. Examples include high-performance liquid chromatography (HPLC), gas chromatography (GC), UV-Vis spectrophotometers, mass spectrometers, and dissolution testers.

It’s important to note that the selection of specific manufacturing equipment depends on the type of pharmaceutical product being produced, the scale of production, and the desired manufacturing processes. The equipment used may vary for solid dosage forms (tablets, capsules), liquid formulations, sterile products, or specialized formulations like creams or ointments.

➢ Quality Control Instruments

Quality control instruments are essential in the pharmaceutical industry to ensure the safety, efficacy, and quality of pharmaceutical products. These instruments are used to analyse and test various parameters related to the raw materials, intermediate products, and final products. Here are some common quality control instruments used in the pharmaceutical industry:

- High-Performance Liquid Chromatography (HPLC): HPLC is a widely used technique for separating, identifying, and quantifying individual components in a mixture. It is commonly used for analysing the purity, potency, and impurity levels of pharmaceutical compounds.

- Gas Chromatography (GC): GC is used for separating and analysing volatile compounds. It is frequently employed for testing residual solvents, volatile impurities, and the identification of organic compounds in pharmaceutical formulations.

- UV-Vis Spectrophotometer: UV-Vis spectrophotometers are used to measure the absorption and transmission of ultraviolet (UV) and visible light by a substance. They are employed for quantitative analysis, determining the concentration of substances like APIs, impurities, and other key components.

- Dissolution Tester: Dissolution testing is performed to determine the rate at which a drug substance dissolves from a solid dosage form (e.g., tablets, capsules) into a dissolution medium. Dissolution testers ensure consistent and reproducible release of the drug from the dosage form.

- Particle Size Analyser: Particle size analysers are used to measure and analyse the particle size distribution of solid particles in a sample. They are crucial for ensuring the uniformity and consistency of particulate materials used in pharmaceutical formulations.

- Karl Fischer Titrator: Karl Fischer titrators are used for moisture content determination in pharmaceutical materials. They provide accurate and precise measurements of water content, which is critical for maintaining product stability and quality.

- Fourier Transform Infra-red Spectroscopy (FTIR): FTIR spectroscopy is employed for the identification and characterization of chemical compounds. It helps in analysing functional groups, identifying impurities, and verifying the chemical composition of pharmaceutical samples.

- Chromatography-Mass Spectrometry (LC-MS, GC-MS): LC-MS and GC-MS are hyphenated techniques that combine chromatography separation with mass spectrometry detection. These instruments are used for qualitative and quantitative analysis, identification of unknown compounds, and detection of trace impurities.

- Atomic Absorption Spectroscopy (AAS): AAS is used to determine the concentration of certain elements in pharmaceutical samples. It is particularly useful for analysing heavy metals and other elemental impurities.

- Stability Chambers: Stability chambers provide controlled environmental conditions (temperature, humidity, and light) to conduct stability studies on pharmaceutical products. These chambers ensure that the products maintain their quality and efficacy over an extended period.

These are just a few examples of quality control instruments used in the pharmaceutical industry. The selection of specific instruments depends on the testing requirements, regulatory guidelines, and the specific characteristics of the pharmaceutical products being analysed.

➢ Automation and Process Control:

Automation and process control play a crucial role in the pharmaceutical industry by enhancing productivity, efficiency, and quality while ensuring compliance with regulatory standards. Here are some key aspects of automation and process control in the pharmaceutical field:

- Programmable Logic Controllers (PLCs): PLCs are computer-based control systems that monitor and control various processes and equipment in pharmaceutical manufacturing. They can automate tasks such as ingredient dosing, mixing, temperature control, pressure regulation, and sequential operations. PLCs offer flexibility, real-time monitoring, and the ability to integrate with other systems.

- Supervisory Control and Data Acquisition (SCADA) Systems: SCADA systems provide a centralized control platform for monitoring and managing manufacturing processes. They collect real-time data from sensors, instruments, and equipment, allowing operators to monitor process parameters, make adjustments, and receive alarms or alerts when deviations occur. SCADA systems facilitate data visualization, analysis, and historical data tracking for process optimization.

- Distributed Control Systems (DCS): DCS is a control system architecture that allows for the central control and coordination of multiple processes and units within a manufacturing facility. DCS provides advanced control algorithms, data integration, and fault tolerance capabilities. It ensures seamless communication and coordination among various equipment and subsystems.

- Batch Control Systems: Pharmaceutical manufacturing often involves batch processing, where a specific quantity of product is produced within a defined time frame. Batch control systems automate and optimize the batch processing work flow, ensuring accurate ingredient weighing, precise mixing, and sequential process steps. These systems enhance reproducibility, reduce human error, and provide batch traceability.

- Process Analytical Technology (PAT): PAT involves the integration of real-time monitoring and control tools into the manufacturing process. It enables the continuous monitoring of critical process parameters (e.g., temperature, pressure, pH) and quality attributes (e.g., particle size, dissolution rate) to ensure process efficiency and product quality. PAT helps in identifying and addressing process variations and deviations in real-time.

- Robotics and Automation: Robots are increasingly utilized in pharmaceutical manufacturing for tasks such as material handling, packaging, labelling, and inspection. Robotic systems offer high precision, repeatability, and speed, contributing to improved productivity and reduced human error. They can work collaboratively with humans or operate autonomously in controlled environments.

- Data Analytics and Process Optimization: Automation and process control generate vast amounts of data that can be leveraged for process optimization and decision-making. Data analytics techniques, such as statistical process control (SPC) and multivariate analysis, help identify trends, correlations, and process inefficiencies. This allows for proactive interventions and continuous process improvement.

- Regulatory Compliance: Automation and process control systems in pharmaceutical manufacturing must adhere to regulatory guidelines, including Good Manufacturing Practices (GMP) and 21 CFR Part 11 requirements (for electronic records and signatures). Compliance measures include data integrity controls, audit trails, system validation, and security protocols to ensure the reliability and traceability of automated processes.

By implementing automation and process control systems, pharmaceutical companies can achieve greater operational efficiency, product consistency, and regulatory compliance. These technologies enable tighter process control, reduce batch-to-batch variability, improve product quality, and enhance patient safety.

➢ Safety and Maintenance:

Safety and maintenance are critical aspects of pharmaceutical manufacturing to ensure the well-being of personnel, protect the environment, and maintain the reliability and performance of equipment. Here are key considerations related to safety and maintenance in the pharmaceutical industry:

Safety:

- Hazard Identification and Risk Assessment: Manufacturers conduct thorough assessments to identify potential hazards and evaluate associated risks. This includes identifying chemical, biological, physical, and ergonomic hazards in the manufacturing process. Risk assessment helps prioritize safety measures and implement appropriate controls.

- Standard Operating Procedures (SOPs): SOPs provide detailed instructions on safe work practices, equipment operation, handling hazardous materials, and emergency response. Employees must be trained on these procedures, and regular updates and reviews should be conducted to ensure compliance.

- Personal Protective Equipment (PPE): PPE, such as gloves, goggles, masks, and protective clothing, should be provided to employees based on risk assessments. Proper training, maintenance, and monitoring of PPE usage are essential to safeguard personnel from exposure to hazardous substances or processes.

- Engineering Controls: Engineering controls aim to eliminate or minimize risks through equipment design modifications. Examples include fume hoods, ventilation systems, containment devices, and safety interlocks. These controls help reduce exposure to hazardous substances or prevent accidents.

- Emergency Preparedness: Pharmaceutical facilities should have well-defined emergency response plans, including evacuation procedures, fire safety measures, spill response protocols, and communication strategies. Regular drills and training sessions are crucial to ensure employees are prepared for emergencies.

➢ Maintenance:

- Preventive Maintenance: Regular preventive maintenance activities are conducted to ensure equipment reliability, minimize downtime, and prevent unexpected failures. This includes routine inspections, calibration, lubrication, cleaning, and replacement of worn-out parts.

- Equipment Qualification and Validation: Equipment qualification ensures that the equipment performs as intended and meets regulatory requirements. Validation involves confirming that the equipment consistently produces desired results within specified parameters. These processes establish the reliability and accuracy of equipment performance.

- Calibration: Calibration involves comparing equipment measurements to a known standard to ensure accuracy. Critical instruments and sensors, such as temperature probes, pressure gauges, and pH meters, should be calibrated regularly to maintain measurement integrity.

- Documentation and Record-Keeping: Accurate documentation of maintenance activities, repairs, equipment history, and compliance records is essential. This documentation aids in tracking maintenance schedules, identifying trends, and demonstrating regulatory compliance during inspections or audits.

- Training and Competency: Adequate training should be provided to maintenance personnel to ensure their competence in handling and maintaining pharmaceutical equipment. Training programs should cover safety protocols, equipment-specific procedures, troubleshooting, and adherence to regulatory requirements.

- Spare Parts Management: Maintaining an inventory of critical spare parts ensures timely repairs and reduces equipment downtime. Spare parts should be properly stored, labelled, and periodically reviewed for obsolescence or expiration.

- Vendor Support and Service Contracts: Collaborating with equipment vendors and maintaining service contracts can provide access to technical support, regular maintenance visits, and prompt repair services. Vendors can also provide updates on equipment upgrades or safety enhancements.

By prioritizing safety and implementing robust maintenance practices, pharmaceutical manufacturers can safeguard their workforce, minimize disruptions, and uphold the integrity and quality of their products. Regular reviews, audits, and continuous improvement initiatives should be conducted to enhance safety protocols and optimize maintenance processes.

➢ Emerging Technologies

The pharmaceutical industry is constantly evolving, and emerging technologies are playing a significant role in shaping its future. Here are some notable emerging technologies that are gaining prominence in the pharmaceutical field:

- Continuous Manufacturing: Continuous manufacturing is an innovative approach that enables the uninterrupted, continuous production of pharmaceutical products, as opposed to traditional batch manufacturing. It offers advantages such as improved process efficiency, reduced manufacturing time, enhanced quality control, and decreased resource requirements. Continuous manufacturing also facilitates real-time monitoring and adjustments, leading to better process understanding and optimization.

- 3D Printing of Dosage Forms: 3D printing, also known as additive manufacturing, is being explored for the production of personalized medicines and complex dosage forms. This technology allows for precise and customizable drug delivery systems, including patient-specific dosages, multi-drug combinations, and intricate geometries. 3D printing has the potential to revolutionize drug formulation and improve therapeutic outcomes.

- Artificial Intelligence (AI) and Machine Learning: AI and machine learning are increasingly used in pharmaceutical research and development, drug discovery, clinical trials, and data analysis. These technologies can efficiently process vast amounts of data, identify patterns, predict outcomes, and accelerate drug development processes. AI algorithms are also utilized for virtual screening, target identification, and optimization of drug candidates.

- Internet of Things (IoT): IoT devices and sensors are being integrated into pharmaceutical manufacturing processes to monitor equipment performance, environmental conditions, and process parameters in real-time. IoT enables predictive maintenance, remote monitoring, and data-driven decision-making. By collecting and analysing data, IoT enhances operational efficiency, reduces downtime, and ensures compliance with quality standards.

- Robotics and Automation: Robotics and automation technologies are advancing in the pharmaceutical industry, automating tasks such as material handling, packaging, labelling, and inspection. Collaborative robots (cobots) are designed to work safely alongside humans, enhancing productivity and reducing the risk of errors. Automation improves efficiency, accuracy, and repeatability while reducing the need for manual labour.

- Data Analytics and Big Data: The pharmaceutical industry generates vast amounts of data throughout the drug development process. Data analytics and big data techniques enable the extraction of meaningful insights from these datasets. Analysing large-scale data sets can help identify new drug targets, optimize clinical trials, predict drug responses, and support evidence-based decision-making.

- Virtual Reality (VR) and Augmented Reality (AR): VR and AR technologies have potential applications in areas such as medical training, simulation, and visualization. In pharmaceutical manufacturing, these technologies can be used for virtual process modelling, equipment design, and training on complex procedures. VR and AR enhance understanding, improve efficiency, and contribute to a safer and more immersive working environment.

- Block-chain: Block-chain technology offers secure and transparent data management, traceability, and supply chain integrity. It has the potential to enhance the safety and authenticity of pharmaceutical products by ensuring the verifiability of raw materials, tracking the movement of drugs, and preventing counterfeiting.

These emerging technologies are transforming various aspects of the pharmaceutical industry, from drug discovery to manufacturing and patient care. While some are already being implemented on a broader scale, others are still in the early stages of adoption. Continued research, development, and integration of these technologies are expected to bring significant advancements to the pharmaceutical field in the coming years.